JAMES EDMONDSON

The key to wider adoption of electric vehicles (EVs) will be lower-cost models with a more approachable price point. The most expensive component of an EV is the battery pack.

As well as increasing the energy density and reducing the cost of the battery cells, another avenue to cost reduction is through more efficient packaging of the cells. Some of the key materials inside the battery pack are thermal interface materials (TIMs), which help transfer heat from the cells to the cooling mechanism (typically a cold plate, or coolant channels).

With the trend towards material reduction and elimination within the EV battery pack, will TIMs survive?

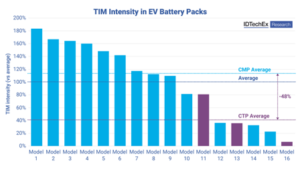

IDTechEx’s report, “Thermal Management for Electric Vehicles 2025-2035: Materials, Markets, and Technologies”, includes a comprehensive breakdown of the TIMs market for EVs, with an analysis of use cases finding that TIMs intensity in production EV models ranged between 0.14kg/kWh to as low as 0.005kg/kWh.

Cell-to-pack reducing TIM intensity

Cell-to-pack (CTP) is the most commonly accepted philosophy when it comes to reducing materials used in a battery pack. By stacking all of the cells together without individual modules, various materials can be eliminated or reduced, including module housings and inter module connections.

This also impacts the TIMs, as rather than having TIMs inside and outside the modules, only one layer of TIM is required directly between the cells and the cold plate. This drastically reduces the TIM quantity per vehicle, with IDTechEx finding an average reduction of nearly 50%, although this varies significantly depending on the specific battery design.

The most extreme reduction IDTechEx has observed in large-scale automotive packs is CATL’s CTP 3.0 design. This uses expandable coolant channels that sit between the cells and make sufficient thermal contact with the cell faces without the need for much TIM. However, a relatively small amount of TIM is still used along the edges of these coolant channels.

While the volume of TIM required drops significantly, these TIMs tend to play a more structural role and hence require stronger adhesion properties (i.e., a thermally conductive adhesive) vs their counterparts used in modular designs (i.e., a more gel-like gap filler).

Thermally conductive adhesives tend to garner a higher price per kg than gap fillers, and therefore, some of the value lost through material reduction can be recuperated through the higher material prices.

Alternative cooling approaches to eliminate TIMs

In addition to material reduction, there are battery designs that can completely eliminate TIMs. Xerotech (a battery manufacturer based in Ireland) utilizes coolant channels between cylindrical cells that are made from a polymer rather than the typical aluminum. These channels can expand to fill the gaps between the cells, forming good thermal contact with the cells.

Austrian component supplier Miba has designed a product called FLEXCooler that replaces cold plates and TIMs with a flexible cooling channel that expands to fill the space around the cells. It claims a reduction in raw material use of 80% when compared with traditional aluminum cooling plates.

Immersion cooling is another route to TIM elimination, by removing the cold plates and directly immersing the cells in a dielectric coolant. This provides excellent thermal homogeneity across the battery cells and pack. However, it comes with its own challenges around fluid sealing, pump selection, and added complexity. For these reasons, immersion cooling has largely remained for high-performance, power-dense battery packs, and IDTechEx predicts that this will remain the main use case.

IDTechEx’s outlook

The greater the adoption of cell-to-pack batteries, the more general the trend around efficiently packing batteries, and the more TIM-free designs will see a reduction in the average TIM content per EV battery pack. However, there is still a vast variety of battery pack designs on the market, and most utilize a significant amount of TIM. Even with the average TIMs reduction, the growing EV market will see the demand for these materials increase with it.

IDTechEx is predicting a 4.2-fold increase in TIMs demand in 2035 compared to 2023 to serve the EV market across on-road markets like cars, vans, trucks, buses, two-wheelers, three-wheelers, and microcars.

IDTechEx is predicting a 4.2-fold increase in TIMs demand in 2035 compared to 2023 to serve the EV market across on-road markets like cars, vans, trucks, buses, two-wheelers, three-wheelers, and microcars.

IDTechEx’s report, “Thermal Management for Electric Vehicles 2025-2035: Materials, Markets, and Technologies”, looks at the thermal management of the battery, motors, power electronics, and cabin, with a deep dive into strategies, components, materials, market shares, and forecasts to 2035.

Dr James Edmondson is a Research Director at IDTechEx

©Copyright MOTORING WORLD INTERNATIONAL. All rights reserved. Materials, photographs, illustrations and other digital content on this website, may not be reproduced, published, broadcast, rewritten or redistributed in whole or in part without prior written permission from Motoring World International

Contact: editor@motoringworldng.com