Each year, April 22nd marks Earth Day, a worldwide event that aims to diversify, educate and activate the environmental movement.

The theme of this year’s Earth Day is “Restore Our Earth”, with the event focusing on natural processes, emerging green technologies and innovative thinking that can restore the world’s ecosystems.

The climax of the event, the Earth Day Live digital event, coincided with the President Biden Administration’s global climate summit, where world leadersmet to discuss the need to take stronger action on climate change ahead of the United Nations Climate Change Conference this November in Glasgow.

Technology could play a key role in the fight against climate change. The continuing growth of electric vehicles and renewable energy is helping to wean the world off fossil fuels. While emerging fields such as carbon capture, utilization and storage, and negative emissions technologies could even help reverse decades of emissions.

As the world marks this year’s Earth Day, here are some of the technologies that will be instrumental in winning the fight against climate change, courtesy of IDTechEx.

Electric Vehicles

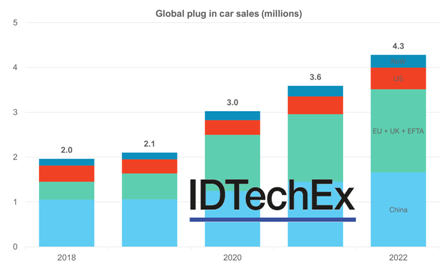

Electric car markets soared in 2020, growing over 40% year on year. IDTechEx expects growth to continue for the next two decades. But this begs the question – why are electric vehicles so immune to COVID-19?

Answer: industrial policy.

The sheer volume of the global car market – some 78 million sales globally in 2020 (LMC Automotive) – means passenger vehicles account for the lion’s share of CO2 emissions from transportation (45% in 2018, IEA).

As a result, passenger cars are a key part of green transport policy coming into place to address new climate goals.

Often, industrial policy is technology agnostic. For example, an automaker can choose to reach an emissions target in any way possible, from improving the efficiency of an internal combustion engine to alternative liquid fuels. But, in practice, battery-electric vehicles offer the lowest-emission solution for the lowest cost in most mobility sectors and are the endgame.

The industrial policy explains the success of electric vehicles against the challenges brought on by COVID-19. Much of 2020’s growth was driven by Europe, which stuck by a transitional year towards new emissions targets (95g of CO2 per km).

Sales of plug-in electric cars nearly doubled, rivaling China, as automakers strived to reach these targets. Critically, Europe is becoming less dependent on Tesla as traditional automakers have ramped up their electrification plans: Ford, Hyundai-Kia, JLR, and VW all made upward revisions to their targets in the first few months of 2021 alone. Their efforts are paying off, as VW recently took the European top spot from Tesla in terms of unit sales, following the success of the e-Up, albeit a 161-mile range city car.

A similar policy is taking shape around the world. China is transitioning away from purchase subsidies and towards a ‘double credit’ scheme, which fines automakers for not selling enough of what it defines as a ‘new energy vehicle’ – a battery-electric, plug-in hybrid, or fuel cell vehicle.

In the US, the Biden administration also has plans to revise emissions targets. The net effect is an industrial policy from around the world will push battery-electric vehicles into the mainstream this decade.

Sustainable Fuels

Coupled with the integration of renewable power sources, electrification offers the most efficient route to decarbonization.

However, not all industries will be able to completely electrify. Aviation presents the most obvious example where electrification and battery technology are unlikely to provide a viable solution for much of the industry. Here, fuels are likely to be needed for the foreseeable future and despite the considerable impact on the industry from COVID-19, sustainable aviation fuels (SAFs) continued to garner interest over the past year.

Most recently, United Airlines announced a partnership with corporate customers to purchase 3.4 million gallons during 2021, while Total begun production of SAF at a biorefinery in France, responding to French government targets for SAF consumption.

These SAF fuels make use of sustainable feedstocks and compared to conventional jet fuels can offer up to an 80% reduction in CO2 emissions.

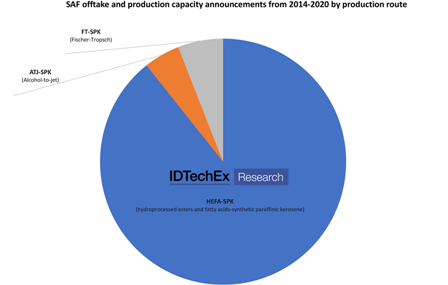

Today, feedstocks are biogenic, that is, SAFs are biofuels. While there are multiple routes to producing SAFs, the vast majority of production capacity is for the production of hydro-processed esters and fatty acids (HEFA-SPK).

As estimated by IDTechEx, by 2025, over 85% of SAF production capacity will be for HEFA-SPK. The process uses vegetable or waste oils, such as used cooking oil, as feedstocks.

While the use of waste oils is generally considered to result in a significant CO2 reduction compared to conventional fuels, the impact from using virgin vegetable oils is more limited due to the impact from land-use changes, especially for feedstocks such as palm, which is grown in areas of high carbon stock and biodiversity.

Mitigating concerns over the sustainability of biofuel feedstocks, synthetic e-fuels offer an alternative to biofuels. E-fuels combine H2, produced from water electrolysis, with a source of carbon, such as from direct-air-capture, to produce intermediates such as methanol and syngas (CO + H2) and eventually drop-in fuels.

Norsk E-fuel, a collaboration between electrolyzer company Sunfire and direct-air-capture company Climeworks, is aiming to have a pilot plant operational by 2023 capable of producing 10 million liters of renewable e-fuels.

The key issue with e-fuels is cost, as both electrolyzer and carbon capture technology is expensive. Further, economic production will be reliant on the use of low-cost electricity, meaning the electrolyzer will have to operate dynamically to make use of excess and low-cost electricity. Dynamic operation is something electrolyzers are generally not well suited to. And given high capital costs, they would ideally need to be operated almost continuously rather than dynamically.

Ultimately, the market for e-fuels is very much in its infancy and improvements to electrolyzer and carbon capture technology are likely needed for commercially viable e-fuel production.

Stationary Energy Storage

The past 10 years have seen considerable growth in the installation of solar PV and wind power onto electrical power grids. However, as the penetration of variable renewable power sources increases, so too does the difficulty of continuously matching supply and demand over various time frames.

Energy storage is set to play a key role in maintaining grid stability and in helping to make renewable power sources dispatchable.

Apart from pumped hydropower, the dominant stationary energy storage technology of today is the Li-ion battery, its development and deployment having benefitted from the scale of the automotive industry.

In their report on the topic, “Li-ion Batteries 2020-2030”, IDTechEx forecasts the market for Li-ion batteries for stationary storage to reach a value of over $50 billion by 2031.

But while Li-ion is set to dominate the market, there is still an appetite for alternative technologies. Redox flow batteries (RFBs) offer one such alternative, where there continues to be steady interest. In March, RedFlow announced a deal to install 2 MWh of their zinc-bromide batteries.

While Australian vanadium mine developer TNG has entered into a joint venture with RFB company V-Flow Tech, aimed at marketing and deploying vanadium flow batteries.

However, for long-duration storage, both Li-ion and RFBs are likely to be too expensive and alternatives based on compressed air, liquid air, and gravitational storage are all being explored. The takeaway is that there are a variety of performance characteristics that are needed for stationary applications, and with battery technology unlikely to be economically feasible for long-duration storage, there will be a myriad of energy storage technologies deployed over the next 10 years to help incorporate increasing levels of renewable power.

Carbon Capture, Utilization, and Storage (CCUS)

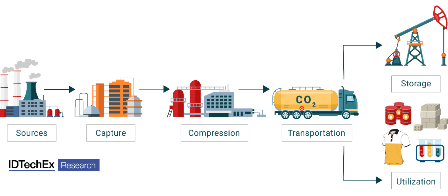

Carbon capture, utilization, and storage (CCUS), or carbon capture and storage (CCS), is a set of technologies used to strip carbon dioxide from industrial waste gases or directly from the atmosphere.

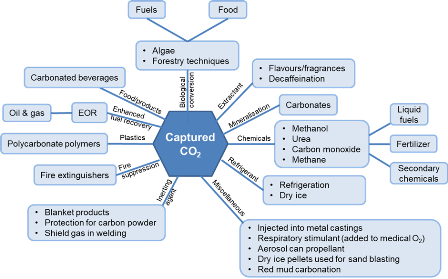

Once the carbon dioxide is captured, it is either stored permanently underground (carbon storage) or it is used for a range of industrial applications (carbon utilization), such as CO2-derived fuels or building materials.

CCUS technologies are likely to play a key role in the fight against climate change, with the UN estimating that CCUS could mitigate between 1.5 and 6.3 gigatonnes of CO2 equivalents per year by 2050.

CO2 can either be captured from a point emissions source, such as a coal-fired power station or directly from the atmosphere in a process called direct air capture (DAC).

Because the CO2 is present in much higher concentrations, it is usually far easier to capture it from point emission sources and almost all CCUS infrastructure today uses point-source carbon capture. Point source carbon capture can drastically reduce the emissions from a single source – a coal-fired power plant equipped with CCUS technology can reduce its CO2 emissions by over 90%, at the expense of some energy efficiency. Point source carbon capture could play an important role in mitigating emissions over the coming decades while renewable energy is still emerging and for industries that are difficult to decarbonize.

Unlike point source carbon capture, DAC technology can directly remove CO2 from the atmosphere and can help to reverse climate change. Although the technology is less mature than point source carbon capture (and is currently much more expensive), it has generated a lot of excitement recently, with DAC companies Climeworks and Carbon Engineering both raising over $100 million in investor funding and Carbon Engineering recently pledging to build a DAC pant capable of capturing over 1 million tonnes of CO2 per year in the Permian Basin.

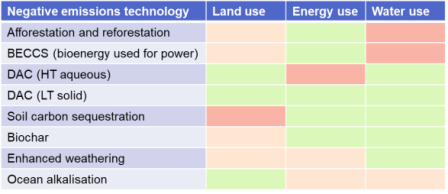

DAC is just one example of a Negative Emissions Technology (NET), i.e., a technology that can actively remove CO2 from the atmosphere. NETs encompass a wide variety of technologies, ranging from afforestation to enhanced weathering of rocks, at a wide range of development levels.

Each NET has advantages and challenges. Afforestation is conceptually simple and cheap to develop. But CO2 capture is slow. And absorbed CO2 often easily re-enters the atmosphere.

By contrast, enhanced weathering could lead to permanent CO2 sequestration. But the long-term ecosystem impacts are poorly understood. And it could be extremely costly to implement.

Ultimately, no one single NET will be a solution to climate change. And the hopes that NETs will develop in the future is not a reason for inaction now.

Once CO2 has been captured, either from a point source or directly from the atmosphere, it can either be buried underground, where it cannot contribute to climate change, or processed into an industrially useful product.

At the moment, almost all captured CO2 is stored underground, with much of it being used for enhanced oil recovery (EOR), where pressurized CO2 is forced into old oil wells to drive out more oil. This is somewhat problematic. Outside of EOR, it is difficult to directly monetize underground storage and EOR generally requires high oil prices to be commercially viable, not to mention the questionable sustainability credentials of using captured CO2 to produce more fossil fuels.

Governments around the world are beginning to implement carbon taxes and other carbon pricing schemes to provide more incentive for companies to invest in CCUS, something which could become a key industry driver for CCUS.

Rather than burying the CO2, it is also possible to convert it into industrially useful products. CO2 can be used as a starting material for several chemical reactions that can be used to create fuels, process chemicals, building materials, and more. This could enable the creation of revenue from captured carbon, providing a commercial incentive to invest in CCUS technology.

However, CO2 is a very stable molecule, meaning that it often requires a lot of energy to convert it into useful products. This makes the process costly and can lead to the release of more CO2, if fossil energy sources are used.

Research is focusing on improving the energy efficiency of CO2 utilization processes while harnessing alternative energy sources such as solar radiation. CO2 utilization currently amounts to a tiny fraction of captured CO2, with the vast majority being stored underground. But experts believe that it has the potential to have a major impact on global emissions if the industry is able to overcome the cost and energy challenges.

Utilizing CO2 that would have otherwise been released as emissions can help mitigate climate change. However, using CO2 in products or services does not necessarily reduce overall emissions in the long term. Quantifying the potential climate benefits associated with and CO2 utilization pathway is complex and challenging and may require a life cycle approach.

The climate benefits associated with CO2 use primarily arise from displacing a product or service that has higher life-cycle CO2 emissions, such as fossil-based fuels, chemicals, or conventional building materials.

©Copyright MOTORING WORLD INTERNATIONAL.

All rights reserved. Materials, photographs, illustrations and other digital content on this website, may not be reproduced, published, broadcast, rewritten or redistributed in whole or in part without prior written permission from Motoring World International

Contact: editor@motoringworldng.com