The resilience of global electric vehicle (EV) sales during 2020 provided some optimism as to the maturing state of the electric vehicle market.

However, sales are still primarily underpinned by government policy, and improvements in cost and performance to Li-ion cells and packs, not to forget other aspects of the vehicle or grid infrastructure, are needed for widespread adoption.

For example, there is a clear trend in moving toward higher nickel NMC and NCA cathode materials for battery electric cars (BEVs) to help improve the energy density of Li-ion batteries, and EV range as a result.

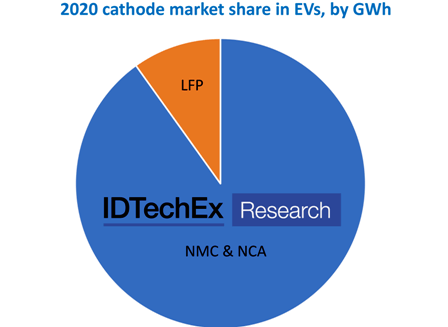

But these high nickel cathodes will not be universally optimal. Segments such as buses or forklifts can benefit from the safety and low cost of LFP(Local field potentials), also known as Llithium iron phosphate battery ( a type of lithium-ion battery using lithium iron phosphate as the cathode material, and a graphitic carbon electrode with a metallic backing as the anode).

There has also been renewed interest in using lithium-ion battery for cars, driven by concerns over the sustainability and supply of critical metals including cobalt, nickel, and even manganese.

Tesla’s Model 3 in China makes use of lithium-ion battery; while Volkswagen and Renault have announced the possibility of using the cathode for entry-level models. In their market report, “Lithium-ion Batteries for Electric Vehicles 2021-2031”, IDTechEx forecast LFPs market share to grow to 15% by 2026, showing that despite the growing popularity of LFP, NMC and NCA will maintain the majority share of the EV market as a whole.

While there is rightly much discussion on the role of cathodes with regard to improving Li-ion performance, cost, and sustainability, a key area of cell development that will help improve Li-ion energy density relates to the anode material, namely, the development of silicon and lithium-metal anodes, the latter often in conjunction with a solid-electrolyte that can offer additional benefits to safety.

Lithium-metal and silicon offer their own advantages and disadvantages. But both can provide significant improvements to gravimetric and volumetric energy density, and given the importance of EV range, numerous automotive manufacturers have partnered with lithium-metal/solid-state and silicon anode technology developers.

Coupled with developments to cell design and the cathode, IDTechEx estimates that commercially available cells for EVs will offer improvements of 30-40% to gravimetric and volumetric energy density by the end of the decade, helping to boost the appeal of EVs to the wider market.

©Copyright MOTORING WORLD INTERNATIONAL.

All rights reserved. Materials, photographs, illustrations and other digital content on this website, may not be reproduced, published, broadcast, rewritten or redistributed in whole or in part without prior written permission from Motoring World International

Contact: [email protected]